Overview

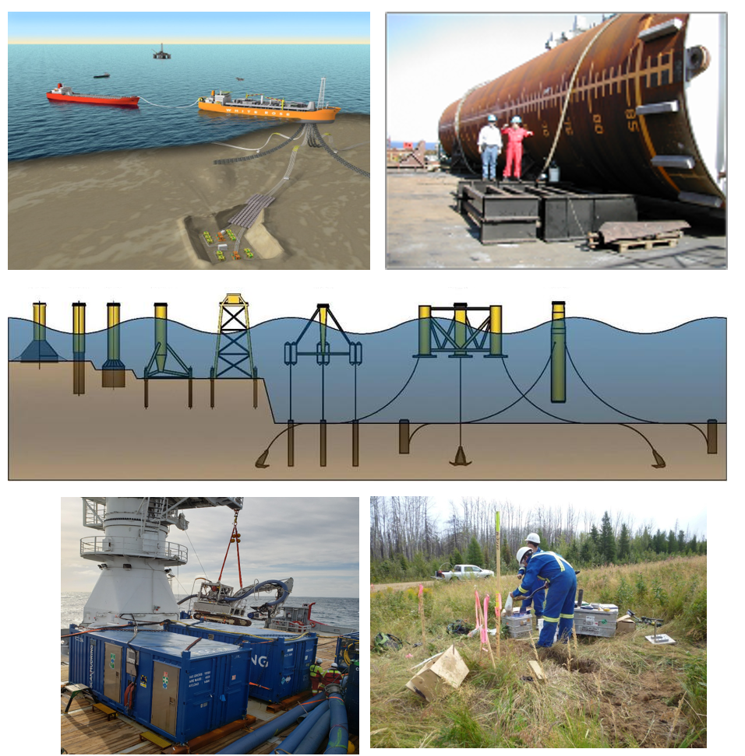

C-CORE provides research-based advice and innovative solutions for the geotechnical aspects of infrastructure projects, both onshore and offshore. Market sectors served include oil & gas; pipeline; mining; Engineering, Procurement, Construction Management (EPCM) Contractors; and government.

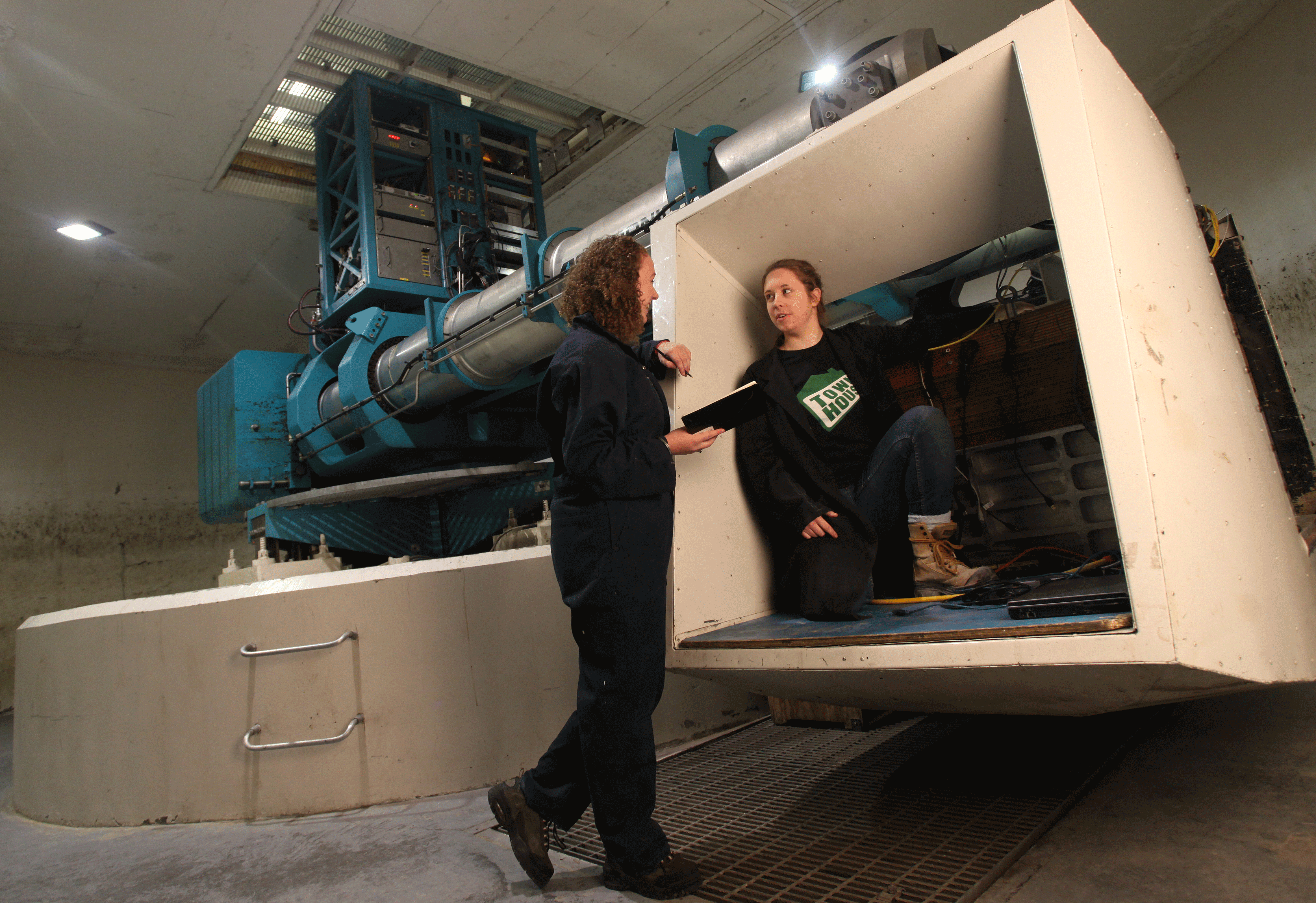

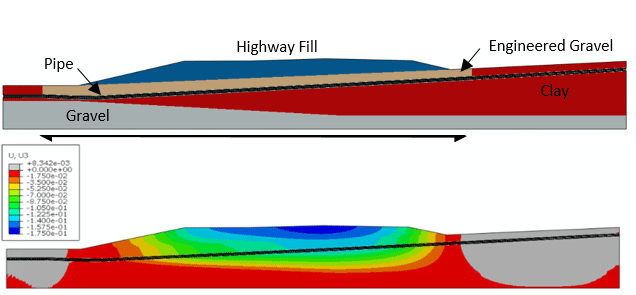

C-CORE’s geotechnical expertise, founded in physical and numerical modelling, includes pipeline testing, ice–seabed interaction, soil–structure interaction and reduced scale physical modelling using our geotechnical centrifuge facility.

Key areas of application

- Foundation and mooring system design, analysis

- Pipeline soil interaction

- Detailed FE modeling

- Commercial centrifuge testing

- Field measurements

- Concept, Pre-feed, feed, and detailed design support

- Validation and verification of understanding of performance, failure modes, and system integrity/reliability

- Structural analysis and design, including comprehensive Finite Element analysis