The Challenge

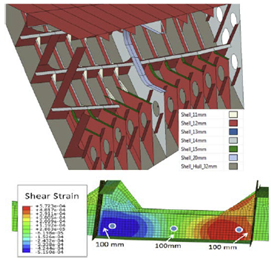

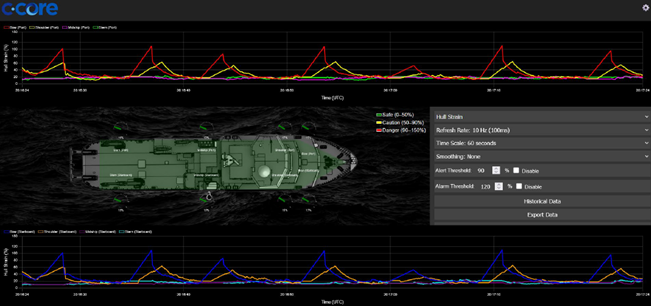

In Arctic environments, extreme local ice pressures are a critical factor in the design of ship hulls and offshore structures. Conservative assumptions about these loads – particularly for non-Polar class drilling rigs – can limit operations to open-water conditions, thereby shortening the drilling season and impacting project economics. ISO 19906 (2010) provides guidance on probabilistic approaches to determining local design pressures for Arctic structures, but its vague implementation guidelines often result in highly conservative designs. The lack of field-verified ice load data under stationkeeping conditions further reinforces this caution.