Our Solution

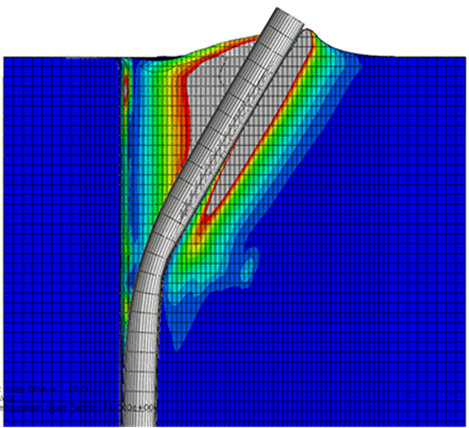

Centrifuge modeling offers a reliable, time-efficient, and cost-effective approach for studying complex geotechnical problems. By reproducing realistic stress conditions at small scale, this technique provides high-fidelity physical data on soil behavior and soil-structure interactions, particularly where gravity is a primary driving force.

C-CORE operates one of Canada’s most advanced centrifuge testing facilities. Our 5.5 m radius beam centrifuge is capable of subjecting payloads to gravitational forces ranging from 10g to 200g, with a maximum rotational speed of 189 rpm. The system is powered by a 500 kW (600 hp) direct-drive motor coupled to a precision 9:1 gear system, and can accommodate:

- 2200 kg at 100g, or

- 650 kg at 200g.

Our system includes over 80 channels of data acquisition, capturing pore pressure, displacement, strain, temperature, and load measurements in real time. Custom-built actuators and instrumentation are engineered to withstand extreme centrifugal forces – up to 100 times their own mass during testing. Our centrifuge is uniquely positioned to conduct cold-weather modeling, enabling tests that replicate the impact of Arctic and sub-Arctic conditions on infrastructure systems.

Typical test campaigns support the performance validation of:

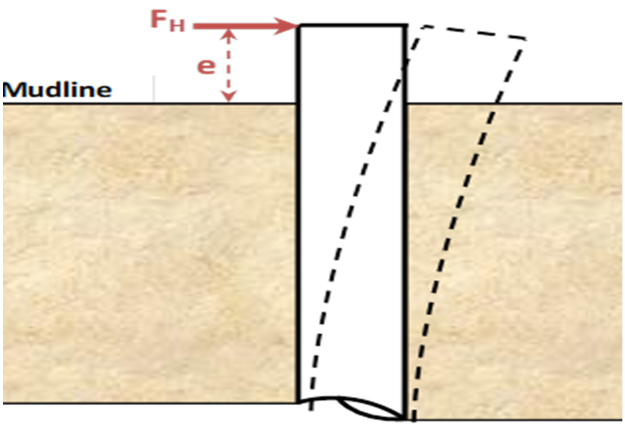

- Pipeline-soil interactions

- Anchor and pile capacity

- Frost heave effects on buried infrastructure

- Embankment and slope stability

Test durations vary depending on the complexity of the scenario – from single-hour simulations to multi-day continuous flights. Our longest test to date ran for 70 hours at 48g, simulating over 18 years of frost heave.

C-CORE’s centrifuge testing provides the critical physical validation required to complement and calibrate numerical models, reduce uncertainty, and improve the safety and reliability of infrastructure design in complex geotechnical environments.